+233(0) 55 257 1173 | +233(0) 59 397 9228

Roofings and steel Ghana Limited tubes are produced from high quality Hot rolled and

Cold rolled steel coils (both MS & Galvanised) on State-of-the-Art Tube mills with high

frequency induction welding conforming to JIS G 3444.

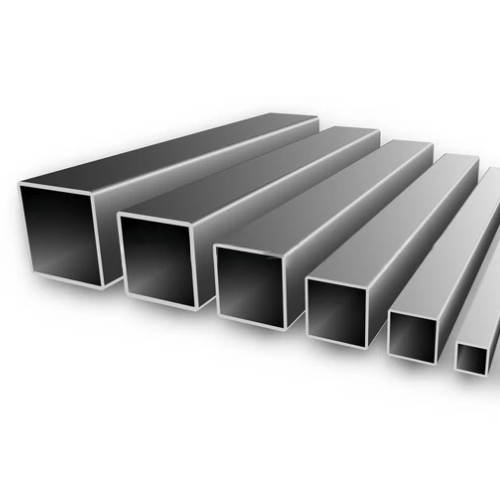

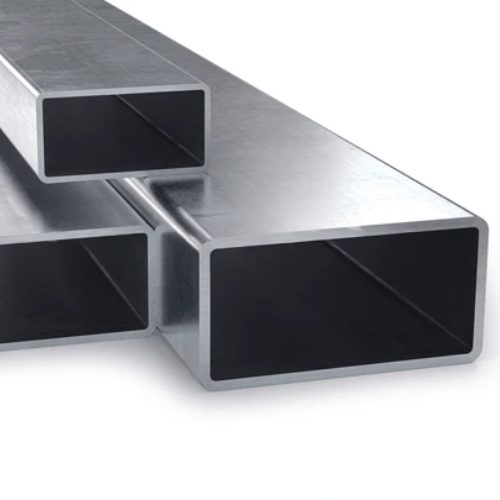

Finished tubes are strapped in bundles of square, rectangular and hexagonal shapes

for stability when stacking or loading into various modes of transportation.

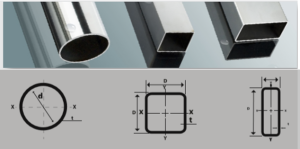

Finished tubes are in shapes of round, square and rectangular as shown below.

Low initial cost compared to most treated steels. In addition, galvanized steel is immediately ready to use when delivered. It does not require additional preparation of the surface, inspections, painting/coatings, etc. sparing companies more costs on their end.

Longer life. With galvanization, a piece of industrial steel is expected to last more than 50 years in average environments, and can last over 20 years with severe water exposure. There is no maintenance required. The increased durability of the steel’s finished product also increases the product’s reliability.

The sacrificial anode ensures that any damaged steel is protected by the surrounding zinc coating. It doesn’t matter if the steel section is completely exposed; the zinc will still corrode first. The coating will corrode preferentially to the steel, creating a sacrificial protection to the areas that are damaged.

Rust resistance from the zinc coating. The iron elements in steel are incredibly prone to rusting, but the addition of zinc acts as a protective buffer between the steel and any moisture or oxygen. Galvanized steel is very protective, including sharp corners and recesses that couldn’t be protected with other coatings, making it resistant to damage.